Scarab brake fixes are required now on most Ducatis and MV Agustas, as they were pretty badly made to start with. These brakes were a very poor copy of the Lockheed calipers which were starting to appear on racing motorcycles in the late 1960s. The brakes really were being made in a gentleman’s shed rather than in a factory. We will now show you why these brakes are problematic and it is also the reason why most green frames had their front brakes upgraded, losing their Scarabs in the process.

Disc brakes came from aircraft

Disc brakes came from aircraft, as discs were being used on aircraft as early as the second world war and were very expensive to make compared to drum brakes. They only made it onto the first racing car in 1956, until then it was all drum brakes. Of course Lockheed were an aviation and defence company, so their disc brake calipers came from the aeronautics industry.

How Scarab brakes came about

When Ducati were pioneering the 500cc L twin racer, prior to the green frame racers, disc brakes were very new to racing. The Ducati race bikes were fitted with Lockheed disc brakes which performed highly agreeably. The rest of this particular story has to be framed as “allegedly” throughout , but it sounds true to me, either way it’s a great story. At this time, Ducati were in receipt of government funding, which meant some of that money came from The Vatican. Italy was quite the basket case country in the 1970s and business was pretty much conducted as it would be in a communist state. Italian manufacturers, especially those in receipt of government funding, were ordered to ensure that the entire machine and all of its components were made in Italy. A gentleman by the name of Sparriani was tasked with ensuring that the government funds weren’t being abused and ensuring that all of the components were made in Italy. Sparriani was working with the 500cc racers and decided that they needed to have the disc brake calipers made in Italy and not the UK. He got his friend, Mr Mozzi, to copy the Lockheed brake calipers in his shed and told him that he could supply all of Ducati’s disc brakes.

Why the green frame had a rear Lockheed

When Lockheed found out about the green frame bikes using Scarabs all round for the road bike, they threatened to sue Ducati for copying their design. Lockheed knew that taking legal action against an Italian company who were claiming that Lockheed had copied their design was not going to end well. To compromise, Ducati said they would fit a Lockheed as the rear brake and Scarabs to the front and Lockheed agreed to not pursue the matter. Please bear in mind that all of this story was “allegedly”. What is certain is that the Lockheeds do not have the poor manufacturing problems that the Scarabs have. The Scarabs performed very badly, unless you were lucky enough to get a good set, which was very rare. This is why so many green frames and MV Agustas were stripped of their Scarab brakes and were fitted with Lockheeds, Grimace or Brembo calipers. Let’s have a look at the caliper and what we’re left to deal with today.

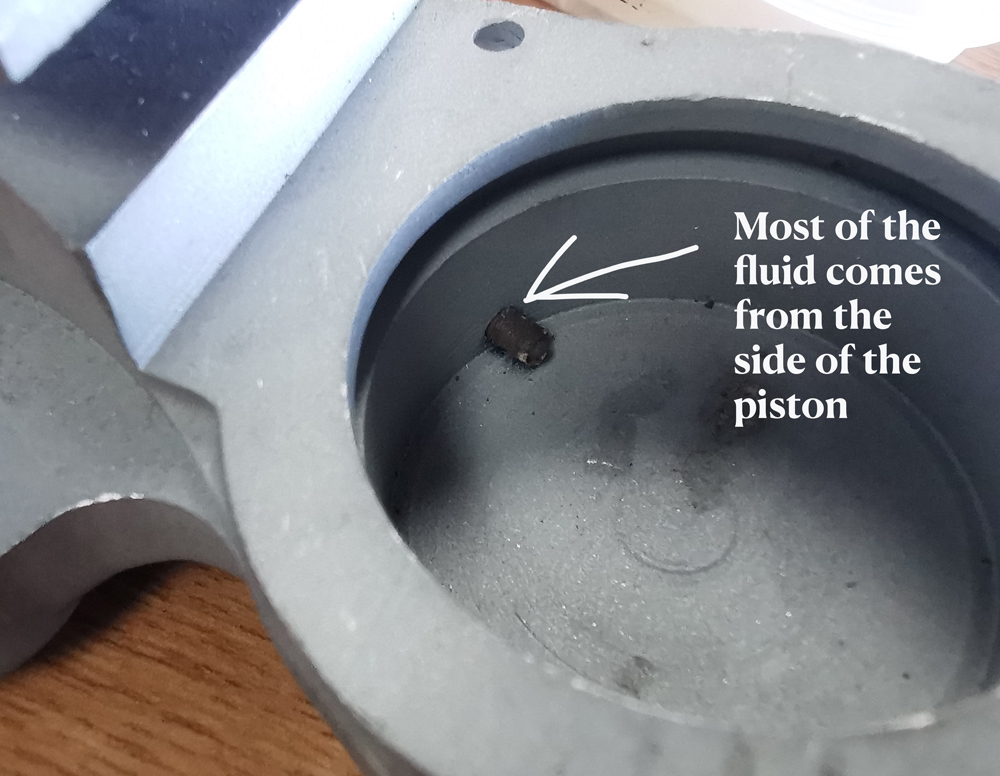

Badly machined when new

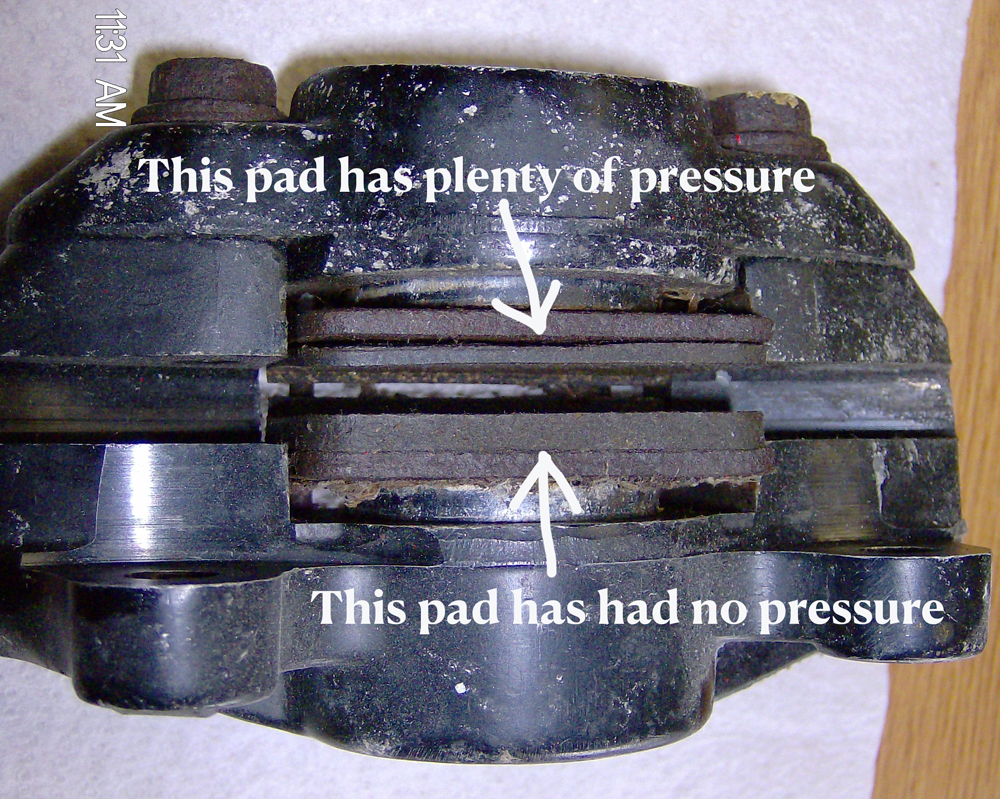

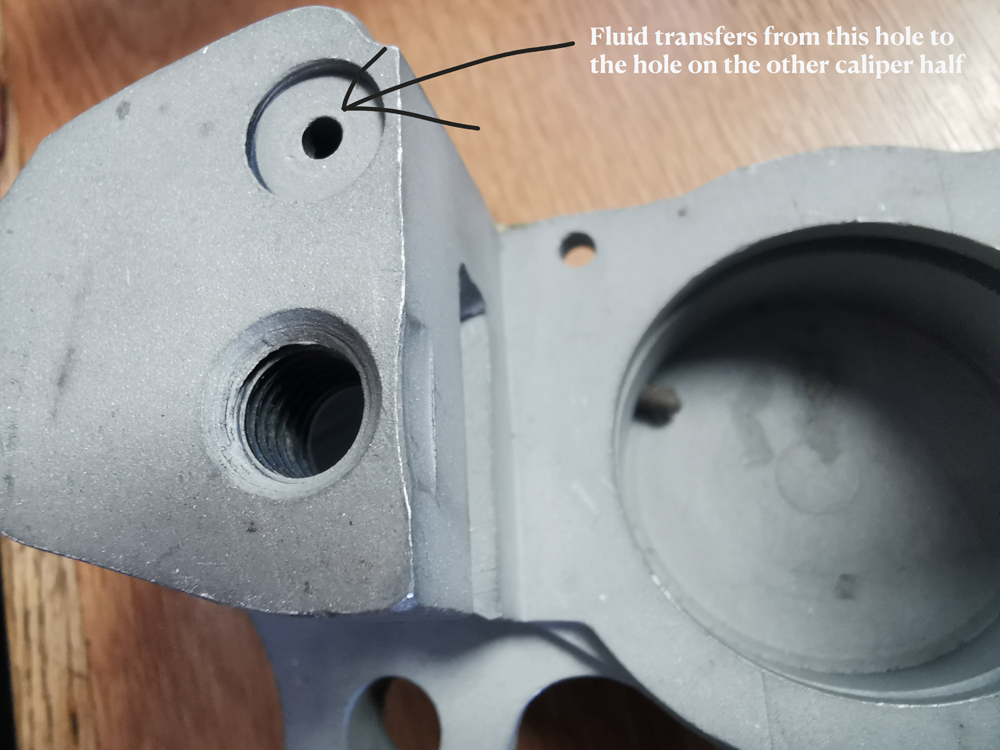

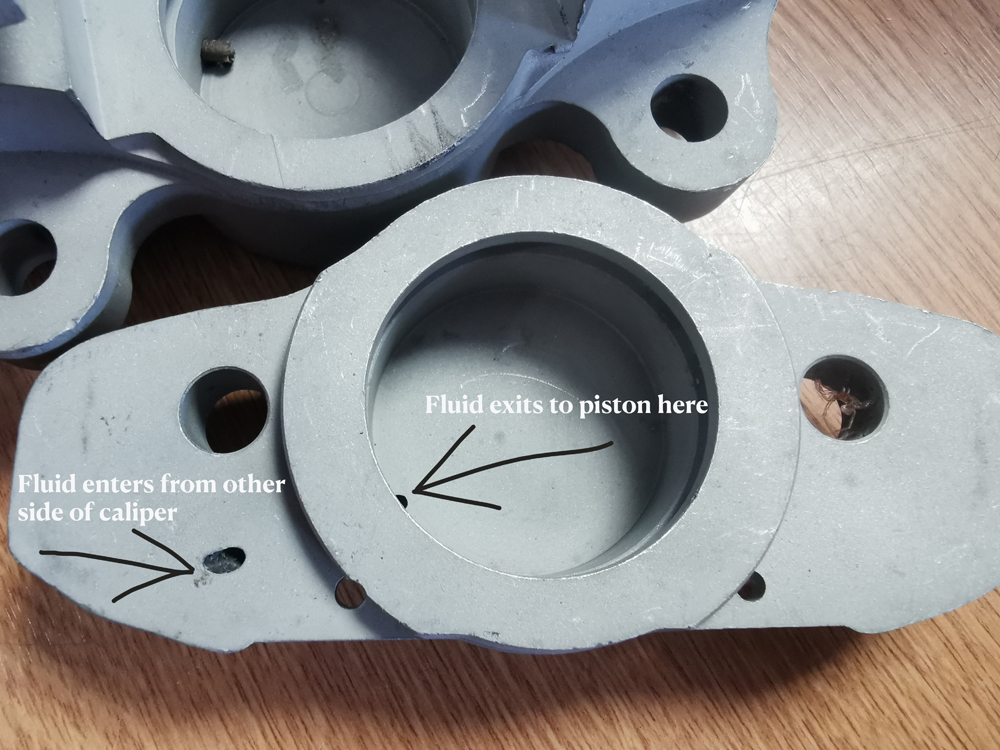

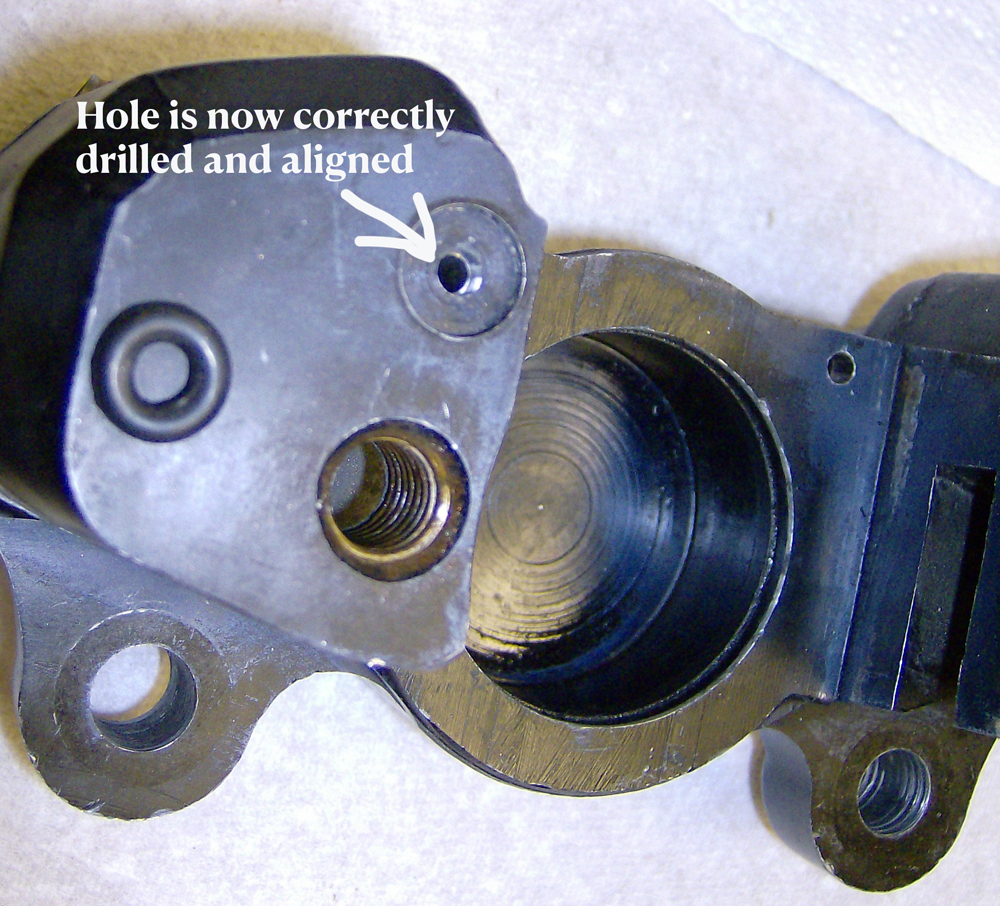

Most of these calipers were badly machined when new. They are made in two halves, splitting length ways with a piston and a pad in each half. There is a transfer port from one half of the caliper to carry brake fluid to the other half. These holes and ports were drilled by hand and were often located in the wrong place for fluid to pass from one half of the caliper to the other. The O ring often also blocked fluid from transferring between the two halves of the calipers. The hole in both calipers, which is supposed to push each piston outwards to press the brake pad, is poorly drilled and forces fluid at the side of the pistons rather than behind them. This prevents the pistons from squeezing brake pads which squeeze the discs and just builds up pressure in the master cylinder. Such poorly manufactured brake calipers are at the heart of seriously poor braking for the motorcycle.

Scarab brake caliper repair

There are a few Scarab brake caliper repairs that work really well and the calibers then offer pretty good braking. The holes transferring fluid from one side of the caliper to the other need to be re-machined correctly. This is a one-shot fix, get it wrong and the cost of saving the caliper is much greater and it will have to be re-anodised. A really good machinist who is prepared to take this job on for the initial repair will need to be found. Most will turn you away and it is a time consuming and costly repair. Fortunately, we managed to get the repair spot-on first time for the Amelia Island green frame which meant we retained the original anodised finish and patina. These calipers were so poorly made when they were new, there is no guarantee that a repair can be completed without damaging the original anodise.

Scarab brake piston replacement

Scarab brake piston replacement is not straight forward, but it does offer the opportunity to repair the problem of brake fluid not getting behind the pistons. Firstly there is no availability of replacement piston for Scarab brake calipers, but Lockheed pistons are still available. However, contrary to popular belief, these pistons are marginally too big and don’t fit. Many companies working on green frames claim that the Lockheed pistons are a perfect fit, but they are definitely not. Either you could have new stainless items made, or you can modify the Lockheed items. As you can see, the Lockheed items have a right angle between the side of the piston and the back of it. To remedy the problem of fluid getting to the back of the piston to push it out towards the pads, it is possible to machine a radius on that right angle to allow fluid to the rear of the piston.

Nipples

Nipples are another problem with these calipers, as they often corroded into the aluminium, as the original nipples were poorly chromed steel items. Once these nipples have disintegrated, they will need to be very carefully machined out of the caliper body. New stainless steel items will need to be fabricated from scratch and carefully machined to create an air tight, and brake fluid tight, seal. This sounds all very straight forward, but it is a long and tedious job which should only be undertaken by a machinist who understands the job and has the skill to get it right. Again, if this job is in any way substandard then very costly repair will need to be undertaken and the original anodise finish will be destroyed.

Scarab brake caliper repair

These Scarab brake caliper repairs transform them from marginally better than useless to really rather good brakes. As well as the calipers themselves, there are serious issues around the master cylinders as well, which we will go into soon. If you need your Scarab brakes repairing or your Ducati or MV Agusta, contact The Motorcycle Broker and we will ensure that your classic stops the way it should stopped when it was new.

- Most collectible Ducati 916 SP - June 20, 2024

- Classic Motorcycles: To ride or not to ride? - June 17, 2024

- Classic Motorcycles: To ride or not to ride? - June 17, 2024

Leave a Reply