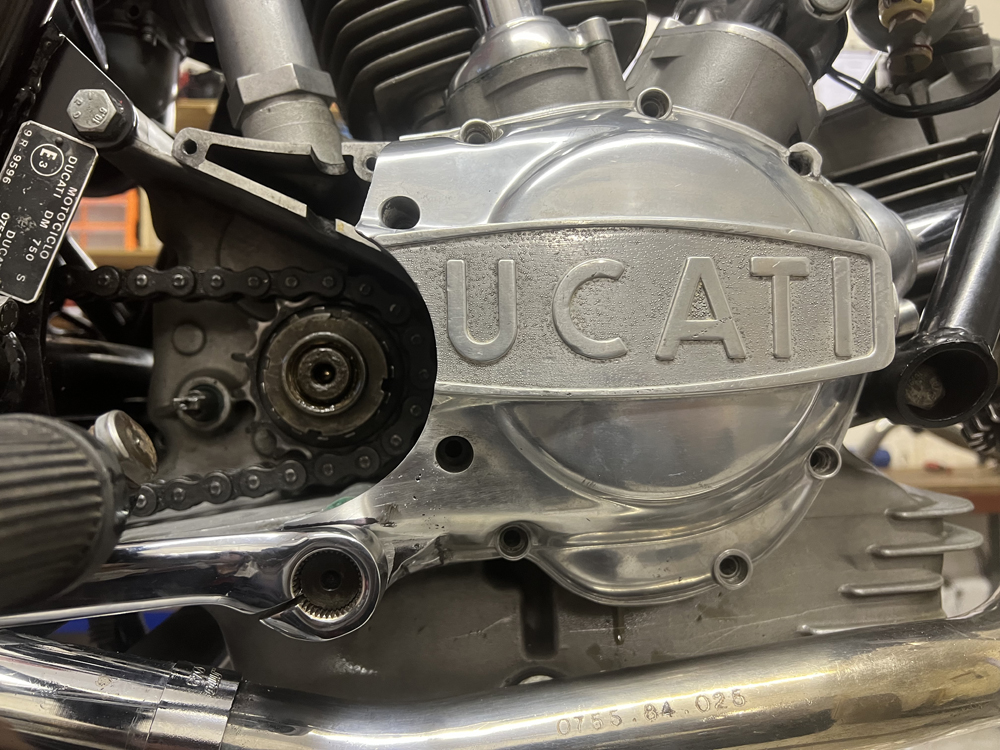

Ducati round case kickstart shaft cover repairs are not just common, but inevitable due to age and poor design in the first place. Round case motors were poorly designed in this area of the motor with kick start oil seal failures requiring full motor strips. We have found a way of doing this without splitting the cases as you can see in this video about the Amelia Island green frame. Ducati round case motors endure particular inadequacy in the design in this particular case in the area where the kickstart shaft passes through the outer case. In their wisdom, Ducati did put a bronze bush into the case to support the kickstart shaft, but the aluminium surrounding the bush is inadequately thin. These problems were fully addressed in the later square case motors, making kickstart oil seals and cases much less problematic. However, in their defence, Ducati were not really interested in how reliable round case motors would be five years after their sale, let alone fifty years on. Buying a new or replica case was no longer possible, someone used to make replica cases but they have since died and are no longer available.

Restored in Italy

This particular machine had been restored in Italy fairly recently and it was a very typical restoration, so we had a good idea of what to expect. By which I mean the bike looked alright, but once it was scrutinised much more closely, the work undertaken was there to make the bike look alright but sustained use would reveal either unresolved problems or badly bodged issues. The frame paint looked alright, until the bodywork was removed, and we knew the bodywork was the incorrect steel type instead of fibreglass. We knew that the bike was originally the very rare sparkle red, instead of the poorly painted black bodywork, but it was incredibly original. It retained the Amal carburettors, the usually long since discarded airboxes and all other parts were present and correct. This was going to make a stunning investment grade 1972 example for our customer. The customer was fortunate to have bought the machine through us on a fixed price contract so that the cost of all of the restoration work, including this kickstart shaft cover repair, were included in the original purchase price of the motorcycle.

Kickstart shaft

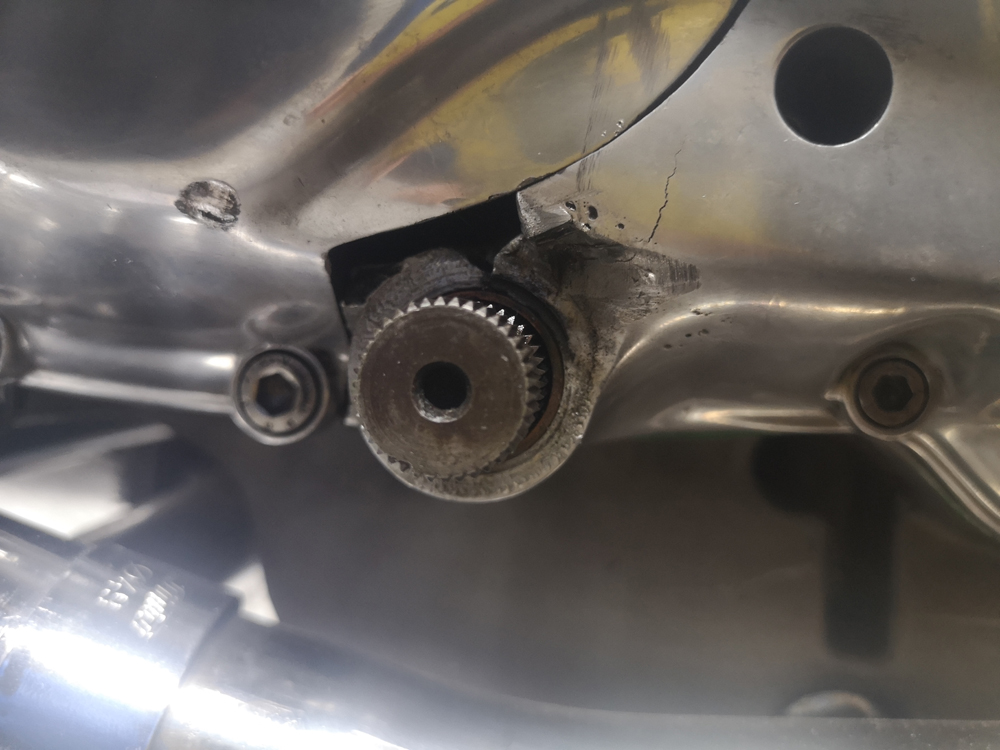

Among other issues, we knew that the casing which housed the kickstart shaft had already been welded and repaired in the past. This part of the casing is highly prone to damage, as I have already stated. The circular part of the case through which the kickstart shaft passes in its bronze bush is very thin to start with. This is compounded over time, because as the aluminium ages it becomes more brittle and the kickstart shaft bronze bush starts to wear. The aluminium of the casing in the bronze bush is only about three or four millimetres thick in which the shaft sits. These cases can be fastened into place with a tolerance of about 2mm and when people have worked on these bikes over the last fifty years, the case can be put back twisted. This will cause rapid wear in the bronze bush and strain the ally case in the most vulnerable, thinnest area around the shaft. Constant use of the kickstart, which is necessary to start the motor, will cause problems with these cases without giving any clues to the person starting the motor. It is easy to see how these cases become so badly damaged over the years. However, if the case is correctly fitted there won’t be a problem.

The original repair

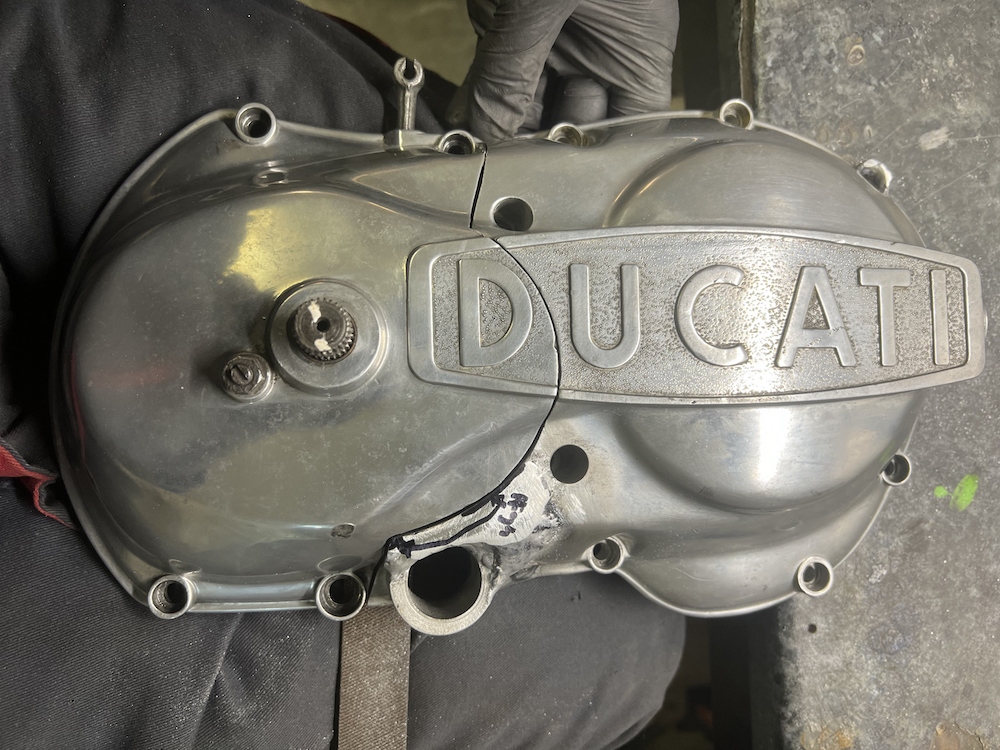

The weld of the original repair looked alright but was messy, we did not wish to dress it because it may well start to leak oil. The weld had not penetrated properly in the first place and the heat had warped the case, along with incorrect fitting of the case over the years. Although the motor was originally oil tight, having gone through several heat cycles it started leaking oil through the weld itself and from the bronze bush which had opened up. These machines, like nearly all classic motorcycles, went through a couple of decades at least when they had little to no value. During this period, owners did not want massive maintenance bills or to look at fixing expensive problems which turned their stomachs. With the ever declining number of engineers who understand these machines, owners turned to anyone who claimed to be able to fix these problems for the lowest price possible. This practise went on throughout nearly all classic motorcycles until values increased substantially to justify doing the job properly. However, engineers now have to deal with undoing the original poor repair before moving onto the original problem. Quite often dealing with the consequences of the old repair is much more of a problem than the original problem in the first place.

Our repair

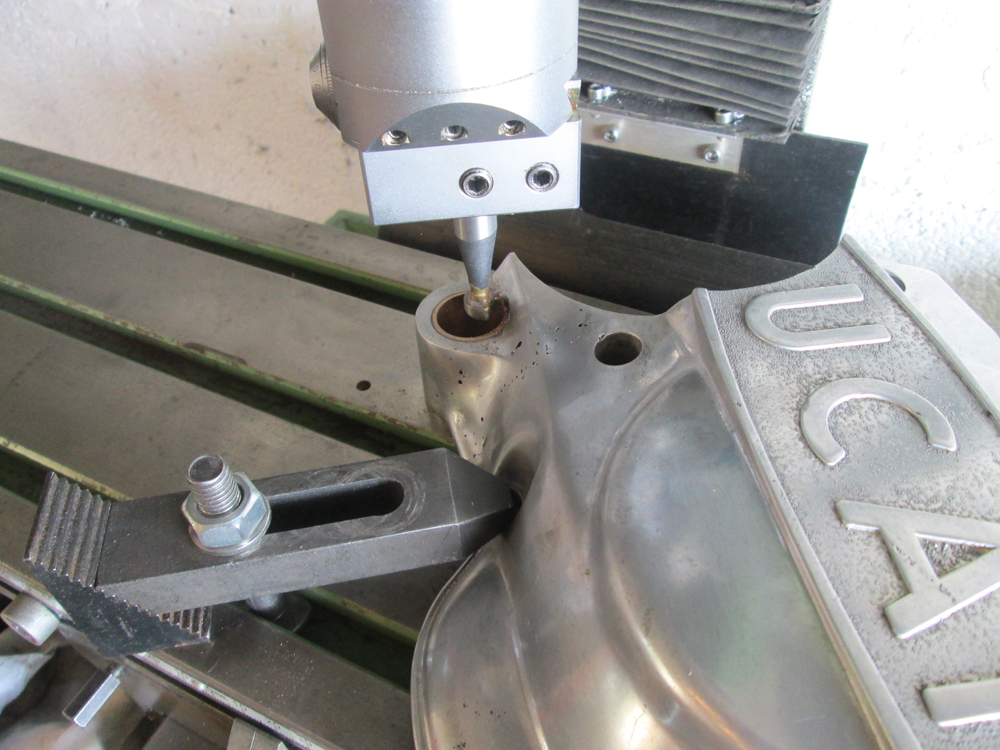

Our repair required us to build up new aluminium weld around the case where it was warped from the previous welding and having been incorrectly fitted. We then had to bring the case flat by hand on a flat sheet of glass with grinding paste. The old weld around the kickstart shaft bush was ground out, as it had become porous, and we built up this area which had become oval from the previous repair. The repair was constantly dressed, offered up, dressed back further, offered up again and this went on numerous times until the case was exactly the correct shape. A new bronze bush was made and pressed in to complete the repair.

The repair was constantly dressed, offered up, dressed back further, offered up again and this went on for a couple of weeks. A new sacrificial bush was made and offered up to create an oval bush correct for the repair.

A constant process

This repair was a constant process of offering the welded and dressed case up, constantly refining the repair, welding it again, dressing it and keep offering it up. Each time the case was welded it had to be bolted to a flat bed to prevent it from warping whilst being heated. Once repaired, this cases will be good for another fifty years, provided the engineer who puts the case back on does so correctly so it sits flat. The machine was now ready for further test riding and remained perfectly oil tight.

- Most collectible Ducati 916 SP - June 20, 2024

- Classic Motorcycles: To ride or not to ride? - June 17, 2024

- Classic Motorcycles: To ride or not to ride? - June 17, 2024

Leave a Reply